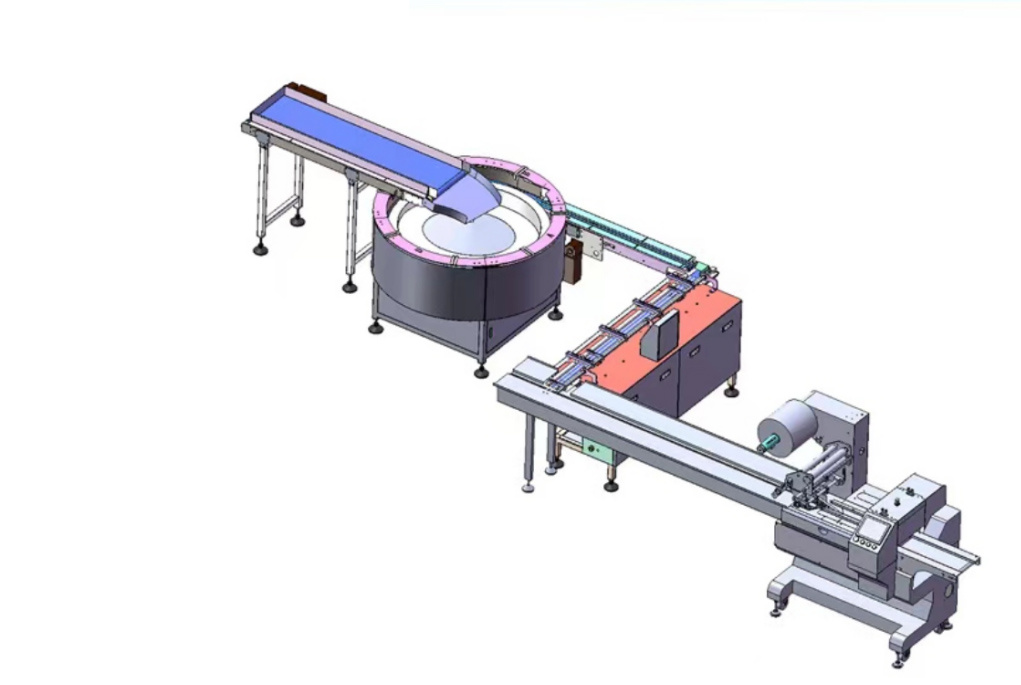

KC-350D Egg Roll Automatic Sorting Line Horizontal flow Packing Machine

APPLICATION:

KC-350D Egg Roll Twist Rice Tong Automatic Sorting Line Pillow Packing Machine is suitable for egg rolls, twists, rice crackers/rice crackers, wafers, egg puff rolls, biscuit sticks, sachima (strips), some Chinese crisp snacks, etc.

MAIN PERFORMANCE & STRUCTURE CHARACTERISTICS

1.Disc sorting automatically arranges products, and the pouring belt is evenly loaded;

2.Automatically sort the products into the packaging machine to save manual material placement;

3Automatically memorize product information to reduce the commissioning time of re-production;

4.important electrical parts adopt internationally renowned brands with stable performance;

PU conveyor belt; Exterior material: 304 stainless steel;

5.PLC control, servo drive, touch screen display; The appearance is neat and beautiful, the structure is compact and reasonable, the operation is simple 6.and flexible, and the operation is fast and smooth.

7.The speed of a single set of material preparation is: 60-150 bags/min

8.The operation is simple, and the man-machine interface sets parameters according to different material sizes.

Scan the code to watch the video

Category:

TECHNICAL PARAMETER

Machine parameters

Parameter Name | Parameter Values |

Device Name | |

Product Length | 30 - 200 mm |

Product Width | 20 - 70 mm |

Product High | 5 - 35 mm |

Packaging Speed | 60 - 150 Bags/min |

Total Power | 6.14 Kw |

Wight | 800 Kg |

Size | 6910×2430×1470 mm |

Power Parameters: | 220V 50Hz |

Important parts brands

NO. | Name | Brand | Brand Origin |

1 | servo motor | Delta | TanWan |

2 | PLC | Delta | TanWan |

3 | HMI | Delta | TanWan |

4 | Frequency converter | Delta | TanWan |

5 | Material inspection eye | Enke | Germany |

6 | motor | Haoxin | TanWan |

7 | Reducer | Starlight | FoShan/China |

Some parts materials and specifications

Name | Material | Specification | Brand | |

1 | Shield | 304 | t=1.0 |

|

2 | Belt pallet | 304 | t=1.5 |

|

3 | Door | 304 | t=1.5 |

|

4 | Side panels | 304 | t=2.0 |

|

5 | Narrow conveyor belt | PU | t=0.8 | Switzerland. Haberst |

6 | Wide conveyor belt | PU | t=1.3 | Shanghai. Wynn |

7 | Catch the slag bucket | 304 | t=1.5 |

PRODUCT APPLICATION SCOPE

More applications

| Food packaging machine | Vacuum packaging machine | Automatic weighing packaging machine | Screw packaging machine | Liquid packaging machine |

| Fruit packaging machine | horizontal packaging machine | Shrink wrapping machine | Sauce packaging machine | Vertical packaging machine |

| Powder packaging machine | granule packaging machine | Vegetable packaging machine | Hardware packaging machine | Medicine packaging machine |

| Commodity packaging machine | Pet food packaging machine | Tissue packaging machine | Nut packaging machine | Hardware packaging machine |

| Acrylic pigment packaging machine | Automatic counting packaging machine | Frozen food packaging machine | Disposable tableware packaging machine | Tea packaging machine |

| Gift wrapping machine | label machine | Filling machine | Multi lane packaging machine | Per-made bag packaging machine |

| Per-made bag Vacuum packaging machine | boxing machine | Carton sealer | Mask packaging machine | Foshan packaging machine |

| Packaging machine factory | Hotel supplies packaging machine | Slipper packaging machine | Disposable dental packaging machine | Auto screw parts packaging machine |

| Express bag packaging machine | Bubble film packaging machine | Aluminum profile packaging machine | Steel pipe packaging machine | Wet wipes packaging machine |

| Furniture screw accessories packaging machine | Non-woven bag packaging machine | Toilet paper packaging machine | stationery packaging machine | Baby product packaging machine |

| Cosmetic packaging machine | Automatic toilet paper packaging machine | Noodle packaging machine | Pasta packaging machine | Snack packaging machine |

| Candy packaging machine | Puffed food packaging machine | Baked goods packaging machine | Powder packaging machine | Plate packaging machine |

| Cup packaging machine | Disposable tableware packaging machine | Disposable skin care product packaging machine | Toy packaging machine | Potato Chips Snacks packaging machine |

| Auto packaging machine with multi-head weighers | Dry Fruit packaging machine | Automatic packaging Machine for slice food | Coffee packaging machine | Bean packaging machine |

Tag list: KC-350D Egg Roll Automatic Sorting Line Horizontal flow Packing Machine

OTHER RECOMMENDATIONS

COMPANY DESCRIPTION

Foshan Kechuang Packaging Machinery Equipment Co., Ltd.

Our main products are: Horizontal flow packaging machine line, vertical packaging machine line, screw packaging line, boxing machine line, per-made bag packaging machine line, 3D packing machine and other full series of packaging equipment,.Our packing machines are widely used in various industries different material packaging.

Our company has strong technical force, excellent machinery and equipment. We can provide customers with technical advice for free, we can design and manufacture non-standard packaging equipment, product quality is reliable, timely service, I hope your brilliant we witness together!

FREQUENTLY ASKED QUESTIONS

How can I get a quote and technical proposal?

How do you handle international shipping and installation?

What is the Minimum Order Quantity (MOQ)?

Do your machines have international certifications?

What about after-sales service?

How do you ensure equipment quality?

MAIN PERFORMANCE & STRUCTURE CHARACTERISTICS

1.Disc sorting automatically arranges products, and the pouring belt is evenly loaded;

2.Automatically sort the products into the packaging machine to save manual material placement;

3Automatically memorize product information to reduce the commissioning time of re-production;

4.important electrical parts adopt internationally renowned brands with stable performance;

PU conveyor belt; Exterior material: 304 stainless steel;

5.PLC control, servo drive, touch screen display; The appearance is neat and beautiful, the structure is compact and reasonable, the operation is simple 6.and flexible, and the operation is fast and smooth.

7.The speed of a single set of material preparation is: 60-150 bags/min

8.The operation is simple, and the man-machine interface sets parameters according to different material sizes.

Scan the code to watch the video

Category: