KCH-350X Three servo wet wipes horizontal flow packaging machine

APPLICATION:

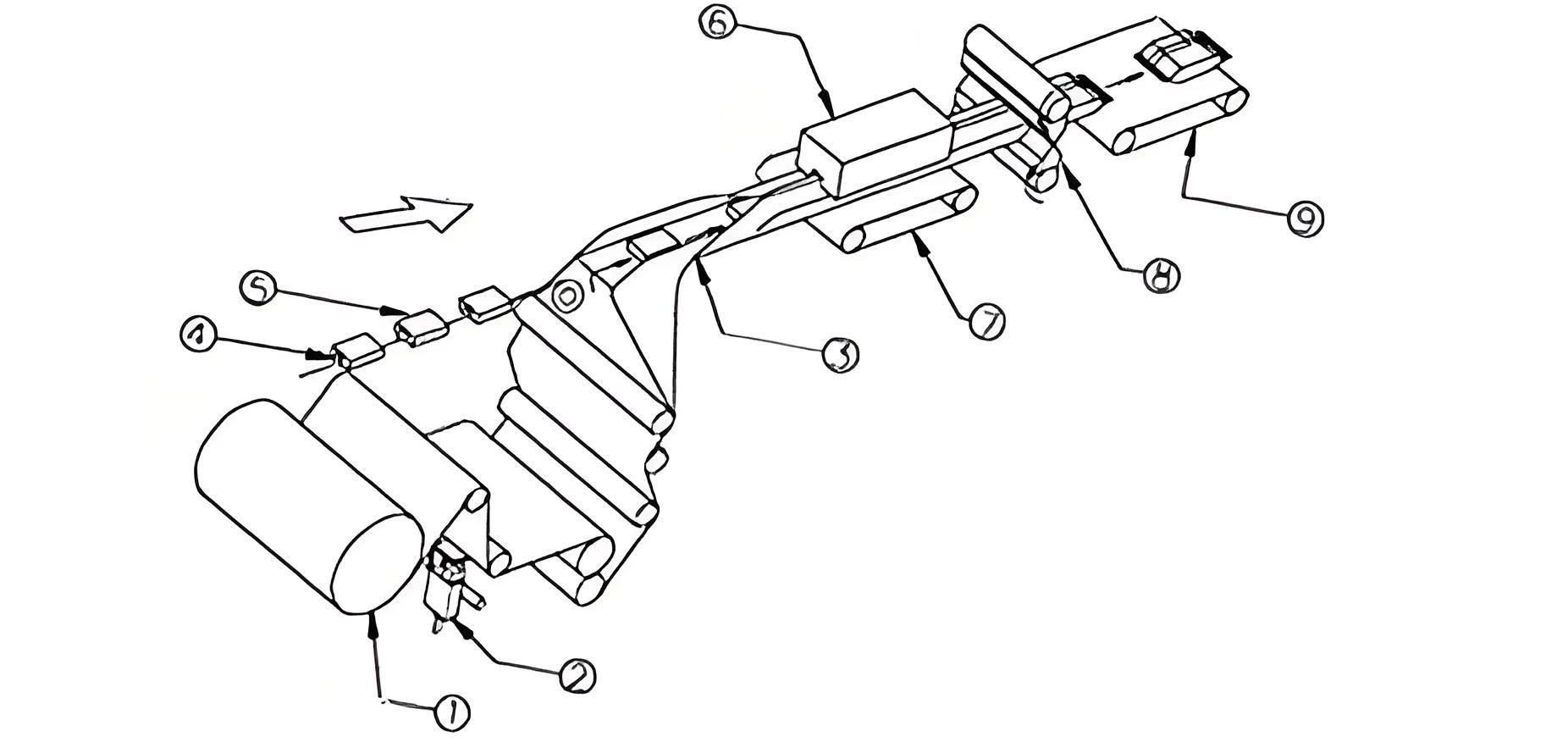

MAIN PERFORMANCE & STRUCTURE CHARACTERISTICS

Scan the code to watch the video

Category:

TECHNICAL PARAMETER

Technical parameters

Type | KCH-350X |

Film width | Max.350mm,film thickness 0.02-0.07mm |

Bag length | 100~1000mm |

Bag width | 80~160mm |

Product height | Max.70mm |

Film diameter | Max.350mm |

Packaging speed | 40~120 Packages / Minutes |

Power | 220V, 50/60Hz, 2.8kW |

Machine size | (L)4520×(W)750×(H)1320mm |

Machine weight | About 490kg |

PRODUCT APPLICATION SCOPE

More applications

Tag list: KCH-350X Three servo wet wipes horizontal flow packaging machine

OTHER RECOMMENDATIONS

COMPANY DESCRIPTION

Foshan Kechuang Packaging Machinery Equipment Co., Ltd.

Our main products are: Horizontal flow packaging machine line, vertical packaging machine line, screw packaging line, boxing machine line, per-made bag packaging machine line, 3D packing machine and other full series of packaging equipment,.Our packing machines are widely used in various industries different material packaging.

Our company has strong technical force, excellent machinery and equipment. We can provide customers with technical advice for free, we can design and manufacture non-standard packaging equipment, product quality is reliable, timely service, I hope your brilliant we witness together!

FREQUENTLY ASKED QUESTIONS

How can I get a quote and technical proposal?

How do you handle international shipping and installation?

What is the Minimum Order Quantity (MOQ)?

Do your machines have international certifications?

What about after-sales service?

How do you ensure equipment quality?

MAIN PERFORMANCE & STRUCTURE CHARACTERISTICS

Scan the code to watch the video

Category: