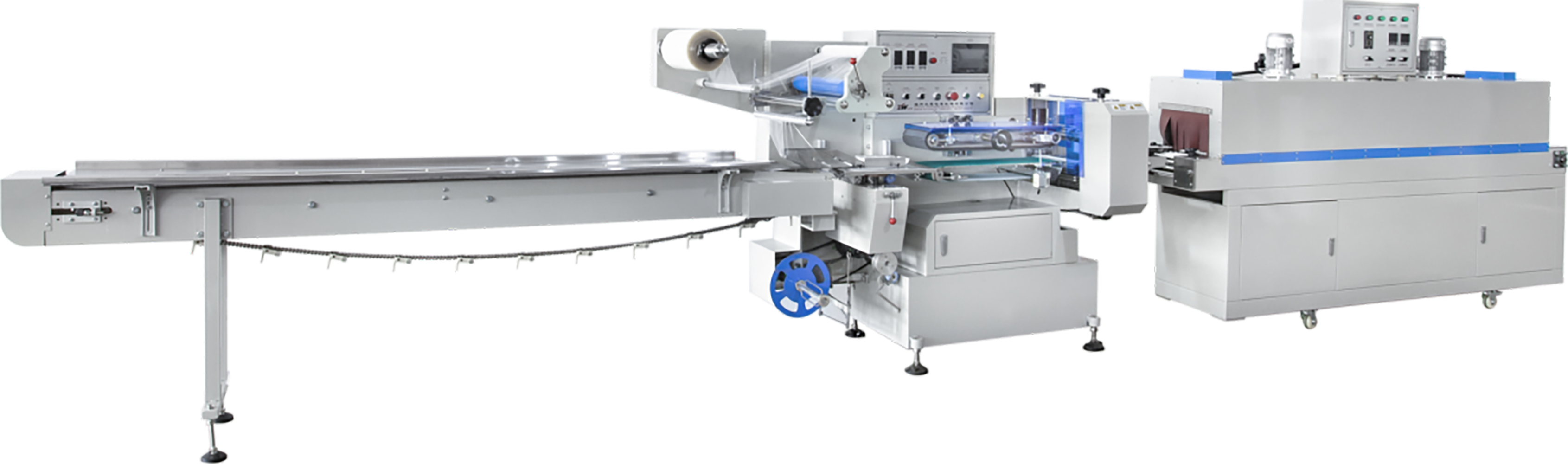

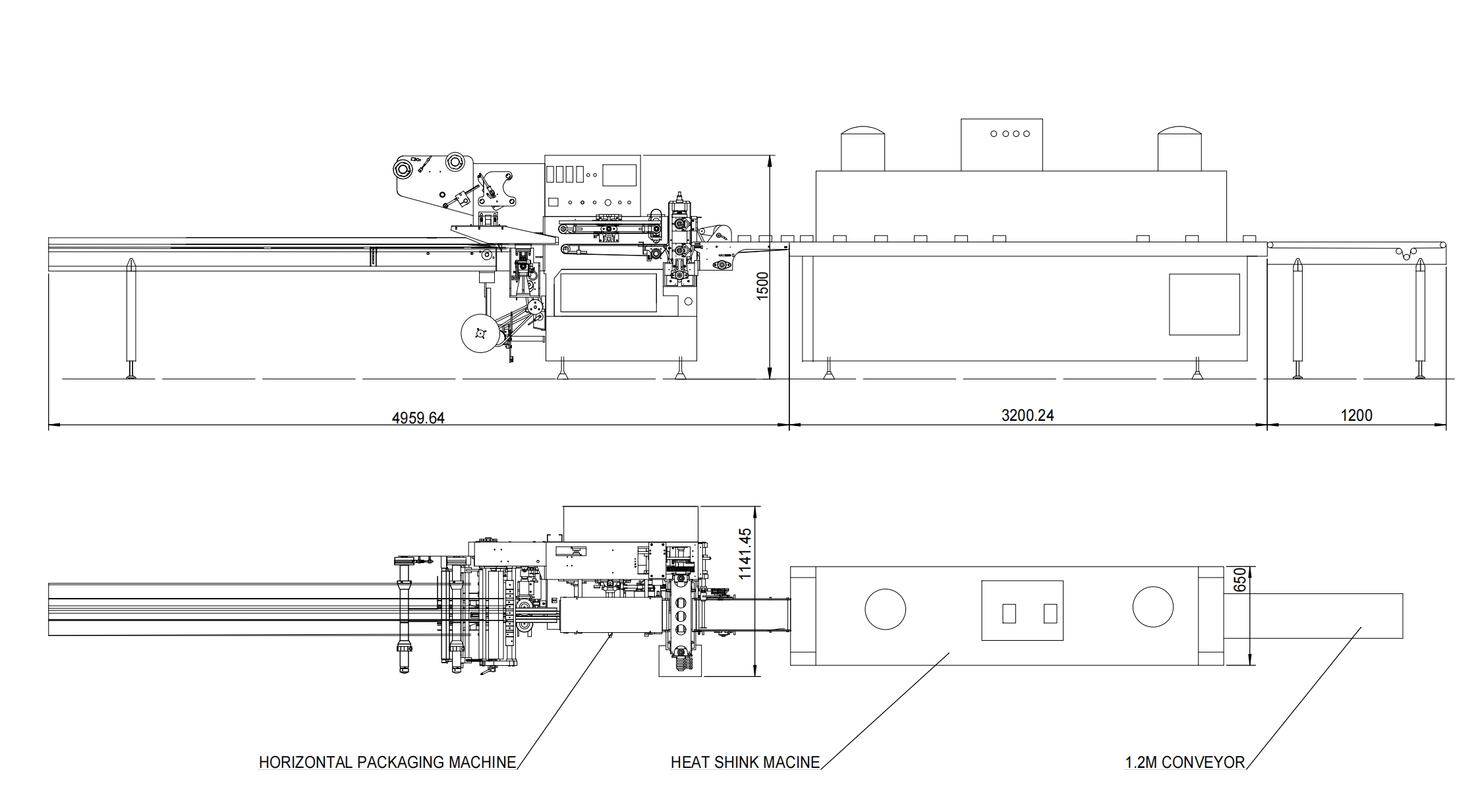

KCH-590 full servo high speed heat shrink horizontal flow packaging machine

APPLICATION:

A Heat Shrink Film Pillow Packaging Machine is a versatile packaging solution widely used across multiple industries due to its ability to securely wrap products in a tight, tamper-evident, and visually appealing package.

MAIN PERFORMANCE & STRUCTURE CHARACTERISTICS

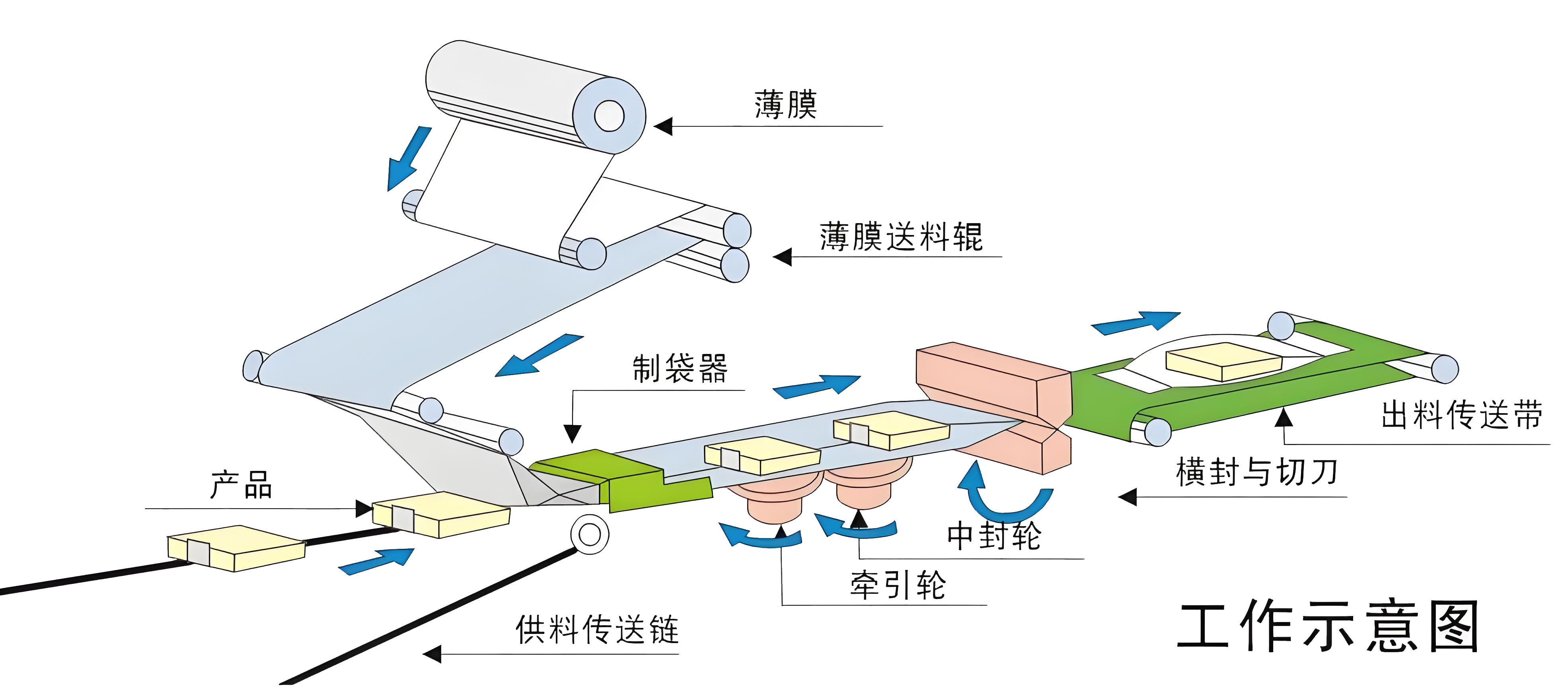

■ Color touch screen control system, using servo motor drive, the whole machine operation is convenient, high stability, high packaging efficiency, low failure rate; bag length, speed and temperature can be adjusted separately, operation is convenient, accurate.

■ Do not damage the package by cutting safety clutch device.

■ High sensitivity photoelectric eye color tracking, mathematical input of sealing position, so that the sealing position is more accurate.

■ Temperature independent PID control, better suitable for a variety of envelope materials.

■ Position the stop function, no sticking knife, no waste of coating.

■ The transmission system is simple, more reliable and easier to maintain.

■ Switch to the product and automatically reverse. After restart, the machine can be directly started for convenient operation.

■ Add waste recycling device to make the packaging more beautiful, saving about 20%-30% of materials compared with the traditional folding film packaging machine.

■ It can be equipped with a coding machine or a printing machine, without manual use.

■ The motor brake control is adopted, and the equipment responds sensitively.

■ The high efficiency double temperature zone of the heat shrink furnace, efficient hot air circulation and automatic temperature control ensure the shrinkage quality.

■ Scope of application: food, medicine, beverage packaging, bowl noodles, milk tea, mosquito coils, wallpaper, exercise books, filters, electrical switches, plastic wrap, garbage bags, all kinds of stationery, industrial parts and daily cosmetic body packaging, etc.

Scan the code to watch the video

Category:

TECHNICAL PARAMETER

Core Function

The machine wraps products (e.g., food, beverages, cosmetics, or industrial items) with a heat-shrinkable plastic film (such as PVC, POF, or PE). The film is sealed longitudinally and transversely to create a sealed pouch ("pillow pack"), which then passes through a heat tunnel or chamber. The heat causes the film to shrink tightly around the product, ensuring a tamper-resistant, durable, and visually appealing package.

special recommendation :

■ This machine adopts Japanese technology, all imported electrical components, is a high-speed automatic packaging machine born in Japan's advanced technology and rich experience.

■ The machine is simple to operate, reliable in quality and stable in performance. The frequency conversion and variable speed are adopted. The whole machine is centrally controlled by PLC, reducing the number of fault points. The heat shrink furnace has high efficiency with dual temperature zones, infinite speed adjustment and automatic temperature control. The high efficiency hot air circulation ensures the shrinkage quality

technical parameters

Configuration details:

PRODUCT APPLICATION SCOPE

More applications

Tag list: KCH-590 full servo high speed heat shrink horizontal flow packaging machine

OTHER RECOMMENDATIONS

COMPANY DESCRIPTION

Foshan Kechuang Packaging Machinery Equipment Co., Ltd.

Our main products are: Horizontal flow packaging machine line, vertical packaging machine line, screw packaging line, boxing machine line, per-made bag packaging machine line, 3D packing machine and other full series of packaging equipment,.Our packing machines are widely used in various industries different material packaging.

Our company has strong technical force, excellent machinery and equipment. We can provide customers with technical advice for free, we can design and manufacture non-standard packaging equipment, product quality is reliable, timely service, I hope your brilliant we witness together!

FREQUENTLY ASKED QUESTIONS

How can I get a quote and technical proposal?

How do you handle international shipping and installation?

What is the Minimum Order Quantity (MOQ)?

Do your machines have international certifications?

What about after-sales service?

How do you ensure equipment quality?

MAIN PERFORMANCE & STRUCTURE CHARACTERISTICS

■ Color touch screen control system, using servo motor drive, the whole machine operation is convenient, high stability, high packaging efficiency, low failure rate; bag length, speed and temperature can be adjusted separately, operation is convenient, accurate.

■ Do not damage the package by cutting safety clutch device.

■ High sensitivity photoelectric eye color tracking, mathematical input of sealing position, so that the sealing position is more accurate.

■ Temperature independent PID control, better suitable for a variety of envelope materials.

■ Position the stop function, no sticking knife, no waste of coating.

■ The transmission system is simple, more reliable and easier to maintain.

■ Switch to the product and automatically reverse. After restart, the machine can be directly started for convenient operation.

■ Add waste recycling device to make the packaging more beautiful, saving about 20%-30% of materials compared with the traditional folding film packaging machine.

■ It can be equipped with a coding machine or a printing machine, without manual use.

■ The motor brake control is adopted, and the equipment responds sensitively.

■ The high efficiency double temperature zone of the heat shrink furnace, efficient hot air circulation and automatic temperature control ensure the shrinkage quality.

■ Scope of application: food, medicine, beverage packaging, bowl noodles, milk tea, mosquito coils, wallpaper, exercise books, filters, electrical switches, plastic wrap, garbage bags, all kinds of stationery, industrial parts and daily cosmetic body packaging, etc.

Scan the code to watch the video

Category: