420/520/620/730 Vertical forming and sealing vacuum packaging machine

APPLICATION:

Vacuum packaging of fresh-cut vegetables, whole grains, beef balls and other foods.

MAIN PERFORMANCE & STRUCTURE CHARACTERISTICS

1. Weilun Chinese and English touch screen display, intuitive operation and simple operation.

2. Mitsubishi PLC computer control system, more stable operation, can adjust any parameters without stopping.

3. Ten sets of parameters can be stored, and the variety can be replaced more accurately.

4. Siemens servo motor is used to pull and touch, and the positioning is more accurate.

5. Independent temperature control system, the accuracy can reach ±1°C.

6. The horizontal and longitudinal sealing temperature is independently controlled, and it can be well applied to various composite films, PE films and other packaging materials.

7. The packaging style is diversified, such as back seal, gusset, bag, punch, etc.

8. Production bag making, sealing, packaging, and printing date are completed at one time.

9. The working environment is clean and the noise is low。

Scan the code to watch the video

Category:

TECHNICAL PARAMETER

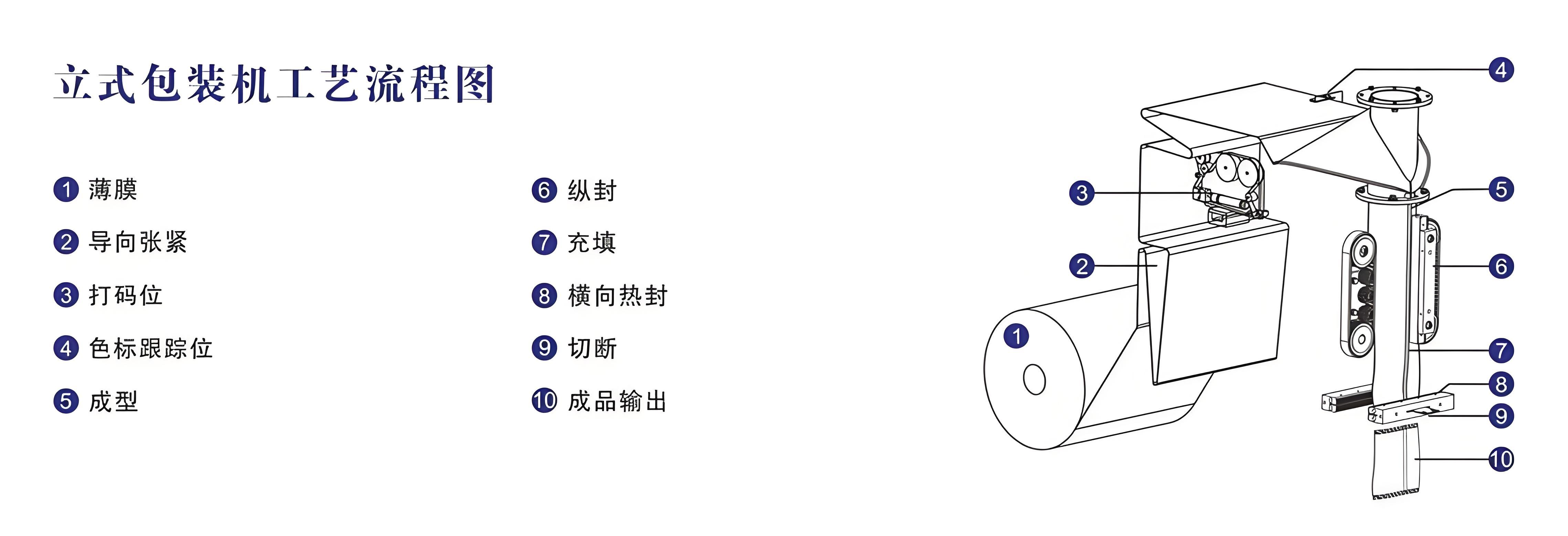

The VP420/520/620/730 fully automatic vertical packaging machine adopts a Mitsubishi PLC full computer control system, human-machine interface, and a large touch screen, making operation simple. Servo film pulling is adopted, ensuring precise positioning and accurate bag size. More than 95% of the entire machine is made of 304 stainless steel. The 10mm ultra-thick film transportation frame makes the film transportation more stable and less likely to deviate. This machine is equipped with an advanced automatic deviation correction function, replacing manual deviation correction.

Packing machine configuration instruction table

PRODUCT APPLICATION SCOPE

This machine adopts a manual weighing method for materials. The weighed products are poured into the bowls of the bowl-type elevator and then into the vertical vacuum packaging machine for vacuum packaging.

This machine takes up a small area and has a high cost performance, making it suitable for family workshops and small and medium-sized processing enterprises.

More applications

Tag list: 420/520/620/730 Vertical forming and sealing vacuum packaging machine

Previous Page

Previous Page

OTHER RECOMMENDATIONS

COMPANY DESCRIPTION

Foshan Kechuang Packaging Machinery Equipment Co., Ltd.

Our main products are: Horizontal flow packaging machine line, vertical packaging machine line, screw packaging line, boxing machine line, per-made bag packaging machine line, 3D packing machine and other full series of packaging equipment,.Our packing machines are widely used in various industries different material packaging.

Our company has strong technical force, excellent machinery and equipment. We can provide customers with technical advice for free, we can design and manufacture non-standard packaging equipment, product quality is reliable, timely service, I hope your brilliant we witness together!

FREQUENTLY ASKED QUESTIONS

How can I get a quote and technical proposal?

How do you handle international shipping and installation?

What is the Minimum Order Quantity (MOQ)?

Do your machines have international certifications?

What about after-sales service?

How do you ensure equipment quality?

MAIN PERFORMANCE & STRUCTURE CHARACTERISTICS

1. Weilun Chinese and English touch screen display, intuitive operation and simple operation.

2. Mitsubishi PLC computer control system, more stable operation, can adjust any parameters without stopping.

3. Ten sets of parameters can be stored, and the variety can be replaced more accurately.

4. Siemens servo motor is used to pull and touch, and the positioning is more accurate.

5. Independent temperature control system, the accuracy can reach ±1°C.

6. The horizontal and longitudinal sealing temperature is independently controlled, and it can be well applied to various composite films, PE films and other packaging materials.

7. The packaging style is diversified, such as back seal, gusset, bag, punch, etc.

8. Production bag making, sealing, packaging, and printing date are completed at one time.

9. The working environment is clean and the noise is low。

Scan the code to watch the video

Category: